The Duravant family of operating companies serve the food processing, packaging and material handling segments.

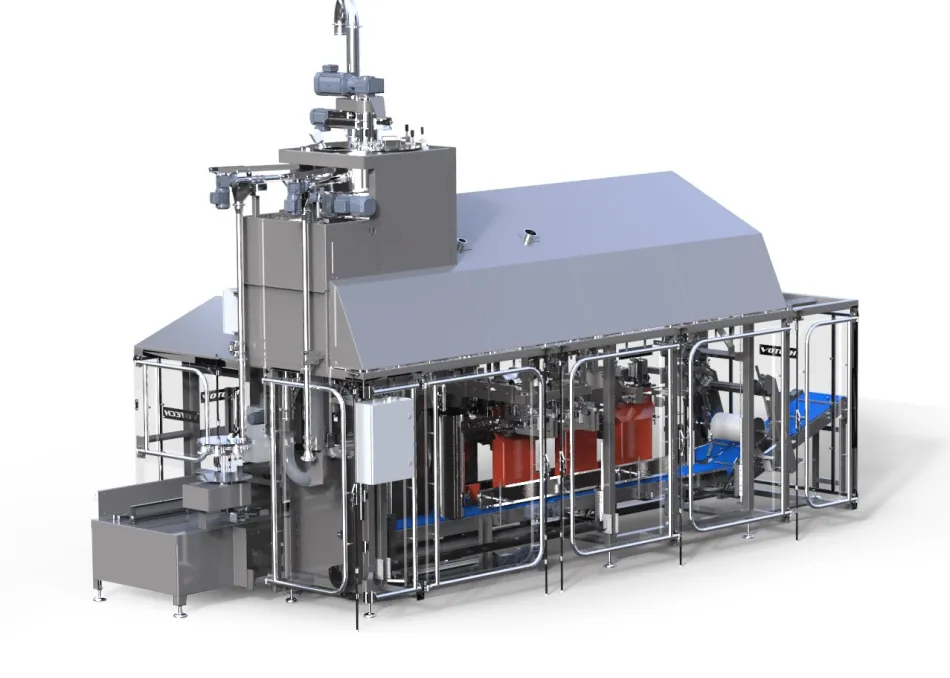

Filling machine: Efficient and accurate bag filling

Looking for a filling machine that combines speed, accuracy, and reliability? Votech designs and manufactures high-quality automatic filling machines for open-mouth bags, ideal for bulk materials such as powders, minerals, animal feed, and mixtures used in agriculture and horticulture. With over 100 years of combined expertise in the packaging industry, we deliver bag filling machines that seamlessly integrate into your production line.

Our bagging machines are available in different models, such as the VLR and VLR-B, depending on your product, bag size, and required output. From semi-automatic filling machines to fully integrated filling lines, Votech ensures tailor-made solutions built for quality and proven performance.

Home » Bag filling machines

This machine is suitable for a wide variety of products, such as animal feed, pet food, seeds, powders, granules, flakes, and more.

- Wide variety of dosing possibilities such as a dosing screw, gravity feeder, dosing belt, and vibratory feeder;

- Wide variety of bag types, bag sizes, and closing methods;

- Double dosing for high capacities or single dosing for lower capacities.

Designed to meet the strict hygienic requirements of products such as milk powders, bakery ingredients, and more.

- Hygienic design with minimized dust formation;

- Precise servo-controlled dosing by means of a vertical dosing screw and bottom-up filling;

- Product and bag top de-aeration for stabilization, minimizing air and enhancing stacking results.

Specialized in processing pet food and products such as animal feed, seeds, granules and more.

- 5cm savings of bag material because of forward transportation compared to sidewards transportation

- Low maintenance costs due to axial moving mechanism equipped with bearings

- Perfectly levelled sealing results through continuous holding of the bag with axial moving mechanism

Want to test your product with our machines?

Get in touch with us today

This tubular bag filling machine is suitable for processing products such as potting soil, sand, gravel and stones, fertilizers, pet food and more.

- 5cm savings of bag material because of forward transportation compared to sidewards transportation

- Low maintenance costs due to axial moving mechanism equipped with bearings

- Perfectly leveled sealing results through continuous holding of the bag with axial moving mechanism

- Bag top de-aeration/vacuum for enhancing stacking results

This machine forms, fills and seals a bag from flat film for products such as potting soil, sand, gravel and stones, bark, fertilizers, hydro grains, salt and more.

- Can be used for bags, growbags and for bales;

- Continuous film transportation and moving seal unit for higher capacities;

- Multiple dosing options to process badly- and free flowing products.

This semi-automatic filling machine is designed for a low capacity solution and is suitable for a wide variety of products, such as animal feed, pet food, seeds, powders, granules, flakes, and more.

- Manual bag placement by the operator;

- Low investment solution.

Robustly built and specially designed for various bulk goods in the heavy duty industry such as potting soil, bark, sand and gravel, stones, animal feed and more.

- Robust vertical lifting movement for distributing the product in the corners of the big bag;

- Heavy duty bottom up filling method for controlled filling and the reduction of dust.

Designed to fill boxes and meet the strict hygienic requirements of products such as milk powders, bakery ingredients, and more.

- Precise servo-controlled dosing by means of a vertical dosing screw with agitator and bottom-up filling for high accuracy;

- Hygienic design with minimized dust formation.

Contact us now

Bag filling machines for every application

A bag filling machine from Votech boosts productivity and efficiency. We offer both semi-automatic and fully automatic bagging machines, equipped with integrated filling systems and various closing technologies. Our machines handle bag weights from 5 to 50 kg and are suitable for: open-mouth bags, tubular film, flat film, big bags and more. We supply automatic filling machines for a wide range of industries, including:

- Powders and minerals

- Animal feed and premixes

- Agricultural products such as seeds and fertilizers

- Horticultural products like potting soil and substrate blends

Every Votech filling machine is engineered, programmed, and manufactured in-house at our facility in Reusel. This allows us to configure each system precisely for your product and desired throughput. We are specialists in delivering turnkey bagging solutions where filling, conveying, palletizing, and stretch hooding are fully integrated.

Industries

Powder filling machine: Hygienic and precise bagging

Filling powdery or poorly flowing materials requires specific expertise. Many bulk products are dust-sensitive, hygroscopic, or even explosive (ATEX). Our powder filling machines are specially designed for these applications and may include:

- Dust-free filling nozzles with efficient extraction

- Net or gross weighing systems with high accuracy

- Vibrating tables for product compaction

- Optional vacuum or gas flush systems

These powder filling machines are ideal for industries where hygiene, precision, and safety are key, such as food processing, pharmaceuticals, chemicals, and animal nutrition. Their modular design allows for easy integration into existing lines or as a complete new filling machine setup.

Reliable Service and Support, 24/7

To minimize downtime and keep your production running, Votech offers 24/7 technical support. Our technicians provide remote or on-site assistance worldwide, always focused on maximizing your uptime. We continually invest in innovation, training, and the digitalization of our service. Through our systems, you always have real-time insight into the performance of your bag filling machine, maintenance schedules, and any error notifications.

Frequently asked questions

Which type of bag filling machine suits my product?

There are various types of bag filling machines, tailored to product type, bag type, bag size, and capacity. Manual machines, also known as semi-automatic filling machines, can fill automatically but require manual placement of the bag. Fully automatic machines handle the entire process from feeding to closing. In addition, there are machines specially designed for powders, granulates, or hygroscopic products.

Which type of bag filling machine suits my product?

The choice depends on product characteristics, packaging format, and required capacity. For dust-sensitive products like milk powder, a powder filling machine with dust extraction and ATEX options is ideal. Coarser materials such as potting soil require a robust filling machine with a gross dosing system and stable bag support. Hygiene standards and the desired level of automation also play a role in determining the right solution. Our product page features various machines that meet these requirements.

What is the difference between manual, semi-automatic, and fully automatic machines?

Manual and semi-automatic machines are essentially the same. The operator must manually place the bags. Fully automatic machines perform the entire process independently, from feeding to sealing. These are suitable for large production lines with high capacities.

Which factors determine the capacity of a bag filling machine?

Capacity depends on the product type—whether it’s dust-sensitive, sticky, or coarse. The type of filling system and the level of automation also play a role. Larger bags take more time to fill than smaller ones. In addition, the bag feeding system and the sealing method affect the filling speed. At Votech, our machines can process up to 1,200 bags per hour, depending on these factors.

What hygiene and safety standards apply?

The food and feed sector is subject to strict hygiene requirements, including EHEDG guidelines and the use of stainless steel contact parts. ATEX certification is important for products that are susceptible to dust explosions. Machines comply with the Machinery Directive and are CE marked. Safety features such as sensors and emergency stops are standard.

What are the maintenance requirements for bag filling machines?

Regular maintenance prevents downtime and extends the lifespan of the machine. It is important to clean dosing units and product contact surfaces. Moving parts, bearings, and the weighing system should also be checked and calibrated regularly. Wear parts such as seals and knives should be replaced on time. Votech provides 24/7 support to ensure the continuity of your production process.

Are there solutions for packaging powders with poor deaeration properties?

Poorly vented powders can lead to air entrapment and unstable bags. Votech filling machines are therefore equipped with venting systems for product compaction. In addition, dust extraction and closed systems ensure a clean working environment. Special filling strategies and screw dosing further improve the process. Vacuum and gas flush systems are available as options for specific product requirements.