The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Home » Transporting systems » Bag transporting system

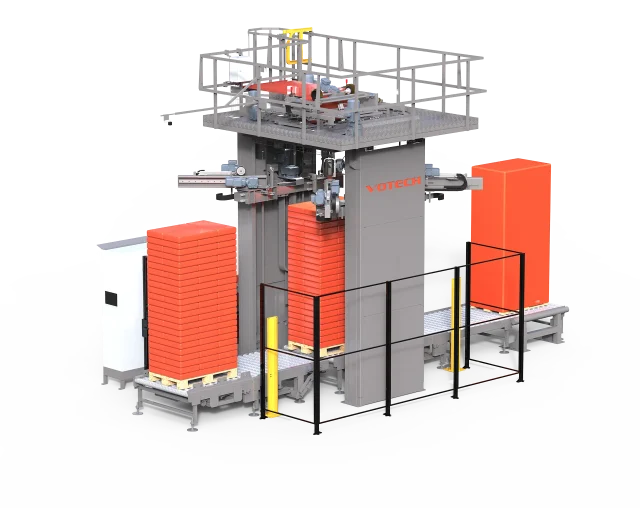

Bag transporting system

Conveyor belts to transport your products inside of your factory, for example from your filling machine to your palletiser.

Technical specification transporting system

- Custom engineered lengths, widths, heights and angles

- Suitable for bags, boxes, bales, growbags and more

- Can process a wide variety of bag types such as open mouth bags, tubular bags, valve bags, net bags and more

- Can process a wide variety of bag materials such as polyethylene, paper, polypropylene, aluminum, net bags and more

- Volume/Weight: 1 – 50 kg

- Multiple grip possibilities to transport your products like rubber, plastic and more

- Powder coating, stainless steel, galvanized and more

Advantages of our transporting system

- Metal detection conveyor

- Checkweigher (suitable for verification and legal certification)

- Inclined or declined conveyor belt

- Corner conveyor

- Spiral conveyor

- Bag lift

- Bag turner and bag kicker

- Bag flattening conveyor or bag press to flatten your product and remove air from the bag

- Bag transporting systems for loading containers

- Separate control system with control cabinet and PLC

- Automatic reject unit when detected metal or deviating weight

- Bag printers and labelers

- Plant hole unit for growbags

- Automatic bag leakage detection

- Bag buffering system

- Distributor roll to distribute the product and remove air from the bag

- Hinged conveyor to dispense at multiple heights

- Sidewards bag sliding conveyors

- Low maintenance

- Ethernet and Wi-Fi connection

- 24/7 service support

Test your products with our machine!

Interested in discovering how a Votech machine performs in practice? We are happy to show you. At Votech, you can schedule a demonstration where our machines are tested under real-life conditions. We can run a demo using your own products at our facility and share the results remotely. Get in touch with the Votech team to discuss available options and suitable dates—we will be glad to guide you through the possibilities.

View our other solutions

Looking for the right packaging solution?

Every production line is different. Votech machines are engineered to match your materials, throughput, and automation requirements. Contact our specialists to explore how this machine can be integrated into your packaging process.