The Duravant family of operating companies serve the food processing, packaging and material handling segments.

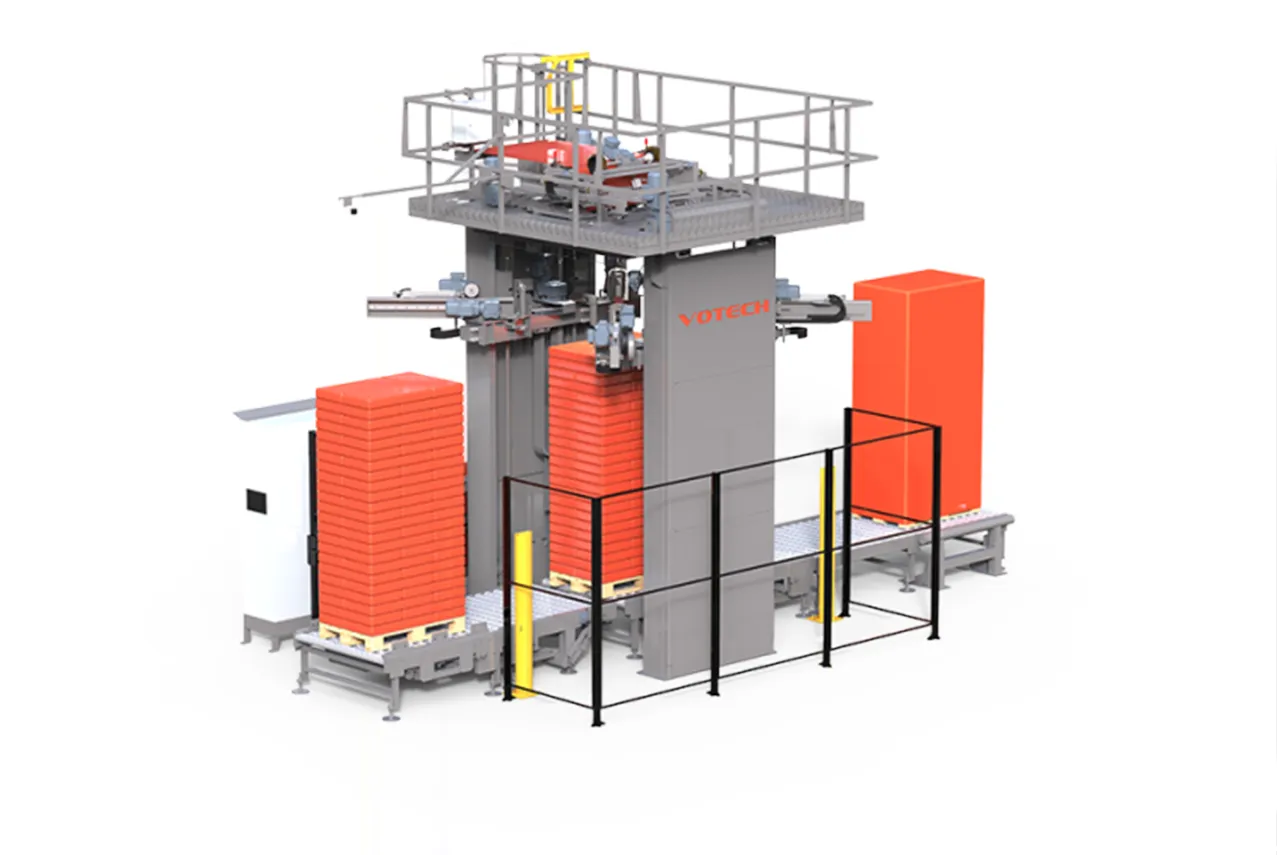

Stretch Hooder: Optimal pallet protection with stretch hooding

An automatic stretch hood machine, also known as a stretch hooder, is the ideal solution for stable and waterproof pallet wrapping. With stretch hooding, a stretchable film is pulled tightly over the pallet, sealing the load from dust and water. This makes it perfect for outdoor storage or transport under variable conditions. The stretch hooder ensures a tight and stable load, whether you’re palletizing bags or boxes, across industries such as powders, minerals, animal feed, agriculture, and horticulture.

Home » Stretch hood machines

Ideal for creating stability of your pallet load and for protecting your product with a waterproof hood from moisture, dust and pests. Perfect for outdoor storage.

- Up to 20% less film usage due to horizontal and vertical stretching;

- Suitable for pallets with bags, boxes, bales, big bags, crates, bins, tiles, insulation material and more.

Pallet wrapper for creating stability and protecting your pallet load.

- Turntable wrapper or rotary arm wrapper;

- Suitable for pallets with bags, boxes and more.

Contact us now

Efficiency and savings with Votech stretch hood machines

At Votech, every stretch hood machine is developed and manufactured in-house in Reusel, allowing us to tailor the machine exactly to your needs and ensure seamless integration into existing packaging lines. Our fully automatic stretch hood machines are designed for:

- Automatic adaptation to various pallet sizes and heights, ensuring maximum flexibility in one system;

- Up to 20% reduction in film usage thanks to advanced horizontal and vertical stretching technology — leading to significant cost savings and less waste;

- A fully enclosed, waterproof stretch hood for reliable protection during transport and storage;

- Quick and easy film roll changes, with optional multi-roll systems for minimal downtime;

- Mechanical film opening (no vacuum needed), maintaining stability in humid or fluctuating temperatures;

- Precise film positioning with independently controlled stretch arms — ensuring tight sealing and reduced product damage.

Industries

Durability and reliability in demanding production environments

Votech stretch hooders are engineered for continuous, reliable operation — even in the most demanding production conditions. Thanks to their robust construction, these machines can process lower-quality pallets without compromising load stability. Additionally, our stretch hood systems contribute to more sustainable packaging by using film efficiently and allowing the use of UV-resistant and recyclable stretch hoods.

Ease of use and customized service

All Votech stretch hood machines feature intuitive control panels and intelligent automation systems, enabling real-time monitoring and adjustments. This ensures user-friendly operation, optimal performance, and fast responsiveness to changing production volumes. We support your packaging process with comprehensive service and maintenance packages, as well as 24/7 technical support — ensuring maximum uptime and smooth operation of your stretch hooder anywhere in the world.

Frequently asked questions

What is a stretch hood machine and how does it work?

A stretch hood machine automatically wraps pallets with a stretchable film hood, also known as stretch hood film. The machine opens a section of film and stretches it both horizontally and vertically. The film is then pulled tightly over the pallet, creating a waterproof and dustproof seal. This provides stable protection, ideal for both storage and transport, even in humid or outdoor conditions.

What are the advantages of a stretch hood machine compared to other packaging methods?

Because the film is stretched in two directions (horizontal and vertical), up to 20% less film is needed compared to shrink or wrapping methods. The closed hood offers excellent protection against rain, dust, and pests, which is especially important for outdoor storage. Mechanical film opening ensures consistent quality, regardless of environmental factors like temperature. The process is fully automatic and capable of high throughput. The machine is also suitable for various pallet sizes and product types.

What types of film are suitable for use with a stretch hood machine?

Stretch hood machines use special polyethylene (PE) stretch film that stretches both horizontally and vertically. These films may include additional features such as UV protection to shield products from sunlight, static properties for better cling, or printing for logos and product details. Votech machines can handle multiple film rolls simultaneously, allowing continuous operation. This offers great flexibility in film selection and application.

What products are suitable for a stretch hood machine?

Stretch hood machines are suitable for a wide range of pallet products such as bags, boxes, bales, big bags, crates, bins, tiles, and insulation material. The machine automatically adjusts to different pallet sizes and product types. With a capacity of up to 120 pallets per hour and a maximum pallet height of 3 meters, it is suitable for various sectors. This makes the machine ideal for a wide range of packaging needs.

How do you properly maintain a stretch hood machine?

Proper maintenance is essential to ensure reliability and extend the lifespan of the machine. It’s important to clean mechanical components and sensors regularly to prevent dust buildup. Moving parts should be lubricated, and wear on film paths and stretching arms should be inspected and replaced as needed. Keeping the software and control systems up to date is also crucial. Votech offers preventive maintenance services and rapid support in case of malfunctions.

Can a stretch hood machine be integrated into an existing packaging line?

Yes, stretch hood machines are flexibly designed for seamless integration into existing packaging lines. They can work in combination with weighing, dosing, filling, and palletizing equipment to create a fully automated end-of-line packaging process. Thanks to their modular design and options for film feed and pallet detection, they fit into a wide range of industrial setups. Votech supports the entire integration process — from design to installation — ensuring a smooth and efficient production flow.

What are the capacity and dimensions of a stretch hood machine?

Capacity varies per model, but fully automatic systems typically process up to 120 pallets per hour. Votech supplies custom-designed machines tailored to speed, space, and product type. Important specifications include a maximum pallet height of 3 meters. Their modular construction makes them easy to integrate into existing lines.

Want to test your product with our machines?

Get in touch with us today