The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Transport systems for the packaging industry

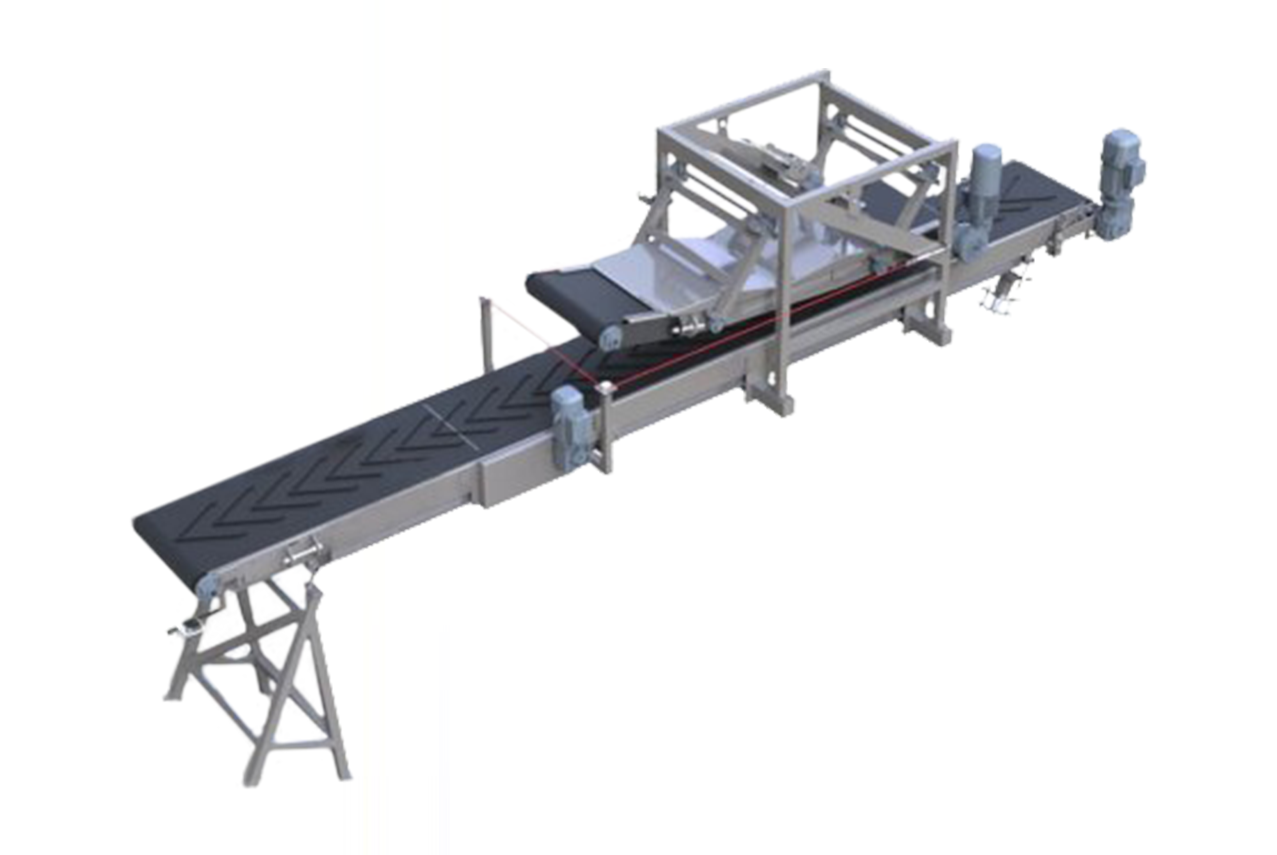

Efficient transport systems are essential in any modern packaging line. They ensure smooth product flow between machines, from the filling machine to the palletizer, and from the palletizer to the stretch hooder. In various sectors, conveyor belts and automated internal transport systems are key to achieving speed, precision, and product safety. Our systems are designed to handle a wide range of packaging types, such as bags, boxes, bales, big bags, growbags, crates, and pallets. With customization in size, materials, and functionality, we always offer a transport solution tailored to your production environment.

Home » Transporting systems

Conveyor belts to transport your products inside of your factory, for example from your filling machine to your palletiser.

- Metal detection, checkweigher, bag lift, bag turners, bag flattening conveyor, bag labelers and more;

- Suitable for bags, boxes, bales, growbags and more.

Pallet rollenbanen om producten te transporteren, bijvoorbeeld van de palletiseermachine naar een stretchhood machine, of om de gestapelde pallets daarna te bufferen.

- Rollenbaan, kettingbaan, traversewagen, leeg palletmagazijn, palletlift, sheetlegger en meer;

- Geschikt voor pallets met zakken, dozen, balen, big bags, kratten, bakken, tegels, isolatiemateriaal en meer.

Contact us now

Conveyor belts and roller conveyors for bags and pallets

Roller conveyors form the backbone of many pallet conveyor systems. They are ideal for controlled pallet movement between palletizers, stretch wrappers, stretch hooders, and storage areas. We offer various types, including powered roller conveyors and gravity roller conveyors, suitable for both wooden and plastic pallets. Thanks to a modular design and customizable components, our systems can be adapted to any logistical layout.

Our transport systems are suitable for both bag handling and pallet transport. Bags are conveyed efficiently via custom conveyor belts, while pallets are moved using advanced equipment like turntables, centering units, pallet scales, and combination systems that include shuttle conveyors and scissor lifts. From valve bags and open-mouth bags to wooden or plastic pallets carrying bags, boxes, or bales — our systems integrate seamlessly into any packaging line thanks to their versatility.

Industries

Shuttle conveyors: flexible pallet transport between multiple lines

For production environments with multiple packaging or palletizing lines, shuttle conveyors provide a highly flexible transport solution. These automated units quickly and accurately move pallets between different locations — for example, from several lines to one stretch hooder. Equipped with line identification and automatic control, shuttle conveyors optimize flow, reduce waiting times, and increase processing capacity without requiring extra personnel.

Tailor-made internal transport solutions

We offer a tailored internal transport system for every production process. Whether it’s an inclined conveyor, spiral belt, or bag elevator, our systems can safely move, tilt, rotate, weigh, or inspect products. Pallets are effortlessly transported via roller conveyors, chain conveyors, or shuttle conveyors, with options such as pallet lifts, stackers, buffer systems, and even sheet dispensers for cardboard or film. Each transport system comes with its own PLC-controlled electrical cabinet, fully customized to meet your operational needs.

Frequently asked questions

What is an industrial transport system?

An industrial transport system is an automated solution for efficiently moving products such as bags, boxes, or pallets within a production line. It ensures smooth product flow between machines like filling machines, sealers, and palletizers. This reduces manual handling and increases production speed. Industrial transport systems are typically modular in design and may include conveyor belts, roller conveyors, lifts, or shuttle conveyors.

What types of transport systems are there?

There are various types of transport systems, depending on the product and process requirements. For bags and boxes, options include belt conveyors, bag elevators, flattening belts, and bag turning units. For pallets, systems may include roller conveyors, chain conveyors, shuttle conveyors, pallet lifts, and weighing conveyors. Special systems like spiral conveyors, corner conveyors, and buffer systems are also available. Many setups can be equipped with metal detection, labeling units, or reject systems.

How much does a custom internal transport system cost?

The cost of a custom internal transport system depends on factors such as length, capacity, level of automation, and required functions. Custom engineering, extra features, and integration with existing lines can all influence the price. However, a well-designed system often pays for itself within months or a few years thanks to increased efficiency and reduced labor costs.

How do I choose the right transport system for my production?

The right transport system depends on the product type (e.g., bags or pallets), weight, size, and desired throughput speed. It’s also important to consider how the system will fit into your existing packaging line and whether there’s room for future expansion. A thorough analysis of your process and production environment will help identify bottlenecks and guide the correct configuration. Experts can advise you on material choices, drive systems, and safety requirements.

What are the advantages of automated transport systems?

Automated transport systems increase processing speed and reduce reliance on manual labor. They enable a consistent flow of products, minimizing downtime and boosting output. Workplace safety improves by automating heavy or repetitive tasks. These systems also offer greater accuracy and traceability. Altogether, they contribute to a more efficient and reliable production process.

Can transport systems be integrated with existing machines?

Yes, transport systems can often be integrated with existing equipment such as filling machines, sealers, palletizers, or labeling units. Integration is managed through a PLC-based control system that coordinates communication between machines. Even older systems can often be connected, provided technical compatibility exists. Custom integration solutions ensure seamless operation across different brands and configurations. Good system integration maximizes overall line efficiency.

Are transport systems suitable for smaller productions?

Smaller production companies can also benefit from transport systems, especially when looking to automate repetitive or labor-intensive tasks. Compact and modular solutions are available that scale to match production volume, keeping costs and space requirements manageable. Even small-scale automation often leads to significant efficiency gains and reduces errors or downtime caused by manual work.

What is the difference between a conveyor and a roller conveyor?

A conveyor is a powered belt that moves products along a surface, commonly used for lighter items like bags or boxes. A roller conveyor consists of individual rollers on which products roll, either freely or driven by a motor. Roller conveyors are best suited for heavier items such as pallets. Conveyors offer continuous, controlled movement, while roller conveyors are ideal for buffering or manual handling zones. Both systems are often combined in a single line for optimal product flow.

What is a stretch hood machine and how does it work?

A stretch hood machine automatically wraps pallets with a stretchable film hood, also known as stretch hood film. The machine opens a section of film and stretches it both horizontally and vertically. The film is then pulled tightly over the pallet, creating a waterproof and dustproof seal. This provides stable protection, ideal for both storage and transport, even in humid or outdoor conditions.

What are the advantages of a stretch hood machine compared to other packaging methods?

Because the film is stretched in two directions (horizontal and vertical), up to 20% less film is needed compared to shrink or wrapping methods. The closed hood offers excellent protection against rain, dust, and pests, which is especially important for outdoor storage. Mechanical film opening ensures consistent quality, regardless of environmental factors like temperature. The process is fully automatic and capable of high throughput. The machine is also suitable for various pallet sizes and product types.

What types of film are suitable for use with a stretch hood machine?

Stretch hood machines use special polyethylene (PE) stretch film that stretches both horizontally and vertically. These films may include additional features such as UV protection to shield products from sunlight, static properties for better cling, or printing for logos and product details. Votech machines can handle multiple film rolls simultaneously, allowing continuous operation. This offers great flexibility in film selection and application.

Can a stretch hood machine be integrated into an existing packaging line?

Yes, stretch hood machines are flexibly designed for seamless integration into existing packaging lines. They can work in combination with weighing, dosing, filling, and palletizing equipment to create a fully automated end-of-line packaging process. Thanks to their modular design and options for film feed and pallet detection, they fit into a wide range of industrial setups. Votech supports the entire integration process — from design to installation — ensuring a smooth and efficient production flow.

What are the capacity and dimensions of a stretch hood machine?

Capacity varies per model, but fully automatic systems typically process up to 120 pallets per hour. Votech supplies custom-designed machines tailored to speed, space, and product type. Important specifications include a maximum pallet height of 3 meters. Their modular construction makes them easy to integrate into existing lines.

Want to test your products with our machines?

Get in touch with us today