The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Home » Palletizers » Palletizer VPG

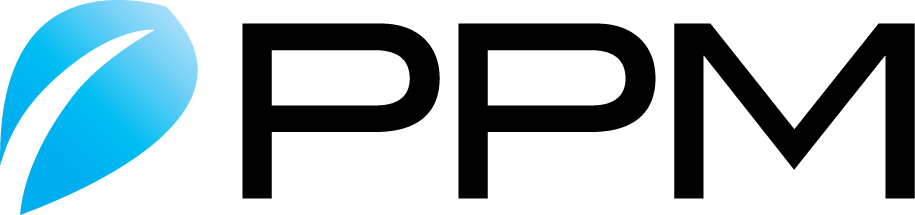

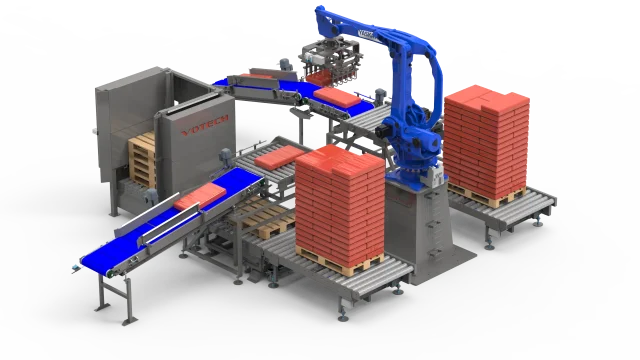

Palletizer VPG

Designed with a gripping head and bag lifting system that ensures a controlled and accurate bag stacking.

Technical specifications palletizer VPG

| Volume/weight | 1 – 50 kg |

| Pallet height | up to 3.000 mm |

| Capacity |

up to 1200 bags/hour |

| Bag type |

Open mouth bags, tubular bags, valve bags, net bags and more |

| Zakmateriaal | Polyethyleen, papier, polypropyleen, aluminium, netzakken en meer |

| Product | Malts, grains, barley, pet food, animal feed, powders, seeds, nuts, legumes, premixes, granules, flakes, additives, salts, fertilizers, chemicals, rice, sugar, cat litter |

Advantages of our palletizer

- Perfectly suitable for big and heavy uncontrollable bags

- Stacking box to keep the load within the pallet size without overhang, for optimal efficiency in warehouses and containers and no bag damage or product loss

- Can be equipped with a bag lift allowing a compact installation size

- Can stack both overlapping and non-overlapping bags

- Each layer of bags can be compressed to guarantee a perfectly stable pallet

- Pallet patterns are easily adjustable by a graphical representation in the touchscreen display

- Bottom, intermediate or top sheet dispenser to create stability or prevent damaged bags

- Automatic empty pallet dispenser

- Optional semi-automatic execution of the palletiser

- Short changeover time and easy to operate

- Low maintenance

- Ethernet and Wi-Fi connection

- 24/7 service support

Test your products with our machine!

Interested in discovering how a Votech machine performs in practice? We are happy to show you. At Votech, you can schedule a demonstration where our machines are tested under real-life conditions. We can run a demo using your own products at our facility and share the results remotely. Get in touch with the Votech team to discuss available options and suitable dates—we will be glad to guide you through the possibilities.

View our other solutions

Looking for the right packaging solution?

Every production line is different. Votech machines are engineered to match your materials, throughput, and automation requirements. Contact our specialists to explore how this machine can be integrated into your packaging process.