The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Home » Stretch hood machines » Stretch hood machine

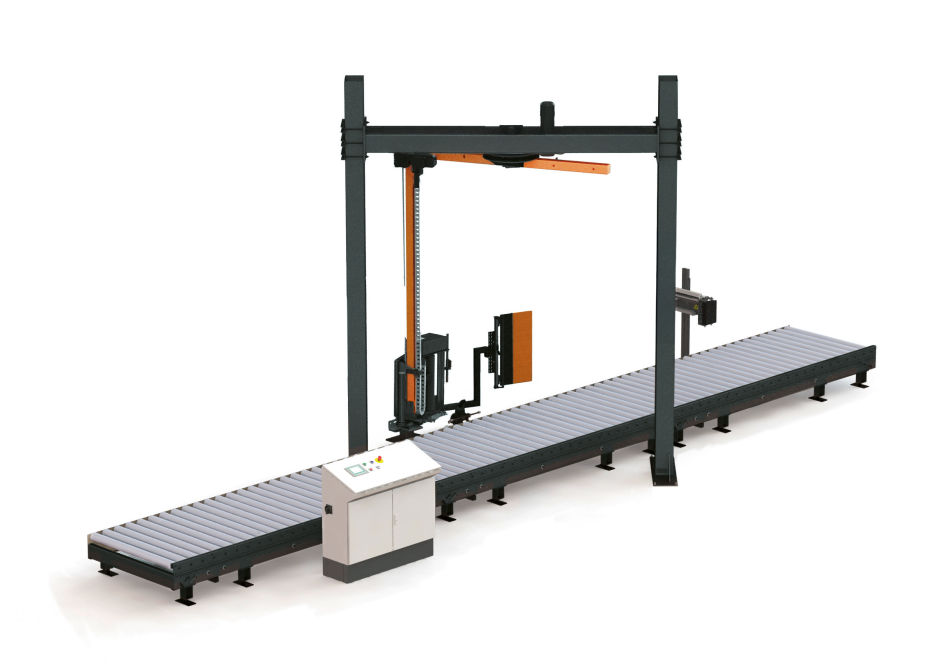

Stretch hood machine VSH

Ideal for creating stability of your pallet load and for protecting your product with a waterproof hood from moisture, dust and pests. Perfect for outdoor storage.

Technical specifications Stretch hood machine

VSH

| Suitable for | Bags, boxes, bales, big bags, crates, bins, tiles and stones, insulation material and more. |

| Film sizes | Suitable for various film sizes |

| Maximum weight | 3.000 kg |

| Capacity |

Up to 120 pallets/hour |

| Pallet sizes | Suitable for various pallet sizes |

| Product |

Pet food, animal feed, powders, seeds, nuts, and legumes, potting soil, bar, cat litter, wood pellets, cocos, hydro grains, fertilizers, sand and gravel, stones, minerals, premixes, granules, additives, salts, chemicals, malts, grains and barley, rice, sugar, potatoes, onions, flakes |

Advantages of our palletizer

- Up to 20% less film usage due to horizontal and vertical stretching

- Opening of the film is done mechanically (not by vacuum), so you are not affected by wind, temperature, humidity and static film

- Waterproof because of the closed off hood, perfect for outdoor storage

- Can process low quality pallets because of automatic detection and adaptation

- Your company logo can be printed on the film

- Can process static film

- Tension arms are individually operating for accurate hood positioning

- Automatically adjusts itself for different pallet sizes

- Film supply at floor level and easy change of the film roll

- Can be equipped with multiple film rolls

- Pallets can be weighed and the info can be printed on the pallet

- Possible to use UV protection film to protect your product from the heat and sun

- Short changeover time and easy to operate

- Low maintenance

- Ethernet and Wi-Fi connection

- 24/7 service support

Experience your product with our machines.

Request a demo now!